Spray Foam Insulation

Enhancing your home or building’s energy efficiency involves managing the infiltration of outdoor air. Perfect for residential or commercial applications, spray foam insulation stands out by delivering, not only an exceptional airtight seal, but also an enhanced insulation value when compared to conventional insulation types. This innovative material is applied as a liquid that expands into a foam, ensuring a complete seal of the building envelope and continuous barrier against air infiltration. This not only contributes to increased energy efficiency but also offers a moisture barrier and pest inhibitor.

The true value is in the cost savings by decreasing your utility bills and your heating and cooling capacity.

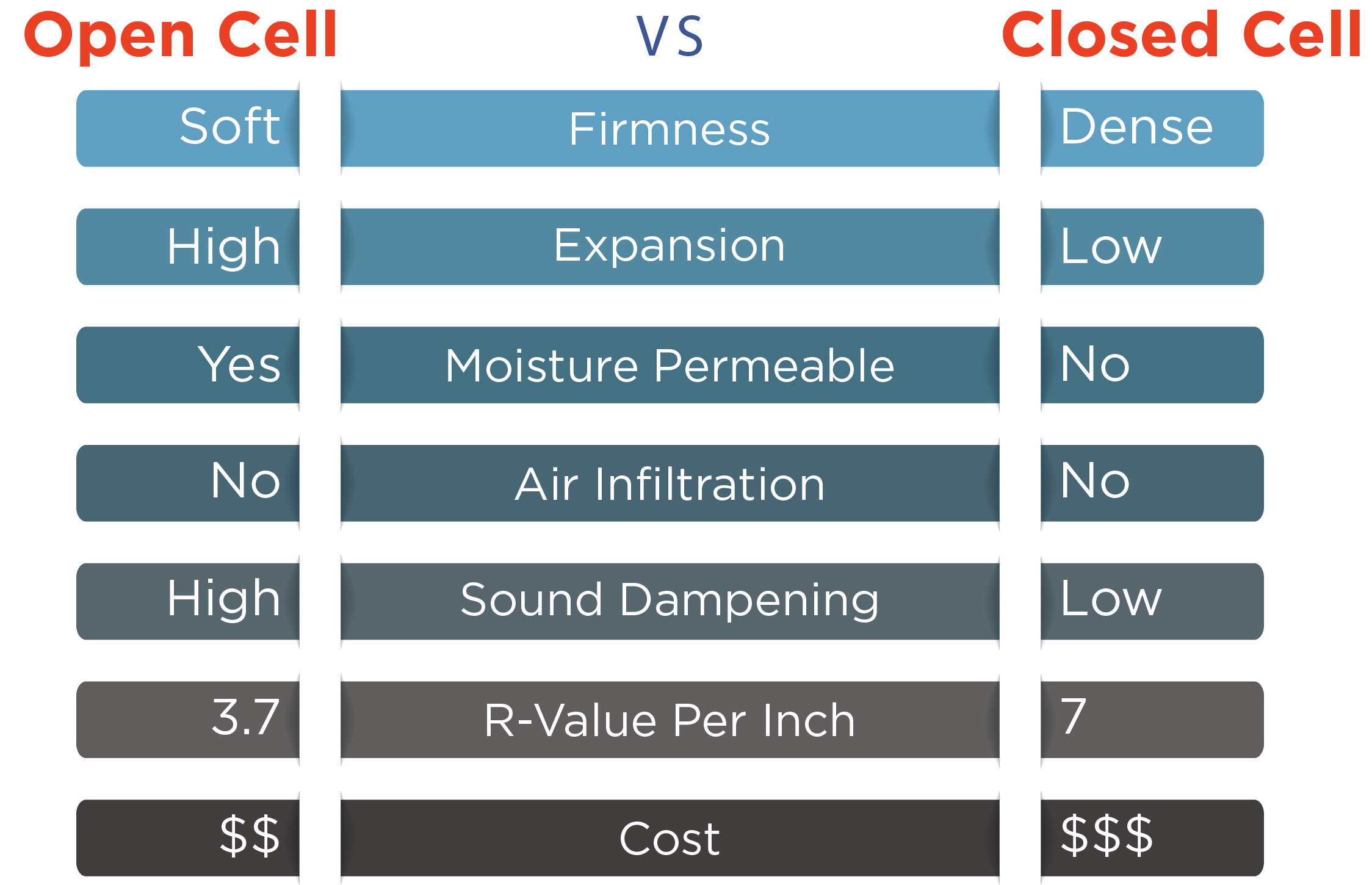

Open-Cell

This type of insulation is less dense and softer, mimicking the feeling of a sponge. The air pockets that are created when the foam expands are not fully enclosed. This offers flexibility of the foam and superior sound absorption.

Closed-Cell

Denser and more rigid, the air pockets of closed-cell spray foam are completely closed circles. This allows it to create a higher insulation value and can be used as a moisture barrier.

Since it doesn’t expand nearly as much as open-cell it can be used in narrower spaces.

Spray Foam Vs. The Others

Not all insulation solutions share the same attributes, and it's crucial to recognize the unique differences. Spray foam has an unparalleled capability to form a continuous and unbroken barrier. This feature goes beyond conventional insulation methods, contributing to its superior performance. By covering and filling all gaps, spray foam ensures an airtight enclosure, creating a more thermally efficient and well-sealed environment.

Energy studies show that fiberglass insulation can lose up to 8% of its R-value before it’s even installed, losing even more over time. Spray foam insulation, however, is made on site and applied immediately. Additionally, the R-value remains the same over time. In areas with limited space to insulate, spray foam can easily double the potential insulating value of a wall where only a few inches of space are available.

-

• R-3.7 per inch (resistance to heat flow)

• Moisture retardant

• Eliminates air gaps and leaks

• Requires less space to achieve desirable R-value

• Save money on utility costs

• Reduces HVAC system capacity

• Improves indoor air quality

-

• R-7 per inch (resistance to heat flow)

• Complete moisture barrier

• Eliminates air gaps and leaks

• Requires much less space to achieve desirable R-value

• Save money on utility costs

• Reduces HVAC system capacity

• Improves indoor air quality

• Adds structural strength

-

• R-2 per inch (resistance to heat flow)

• Made of fine fibers of glass

• Often referred to as batt insulation

-

• R-5 per inch (resistance to heat flow) before settling

• Made from recycled paper

• Chemically treated for flame retardancy, mold and pest resistance

• Can settle up to 25% overtime reducing r-value

Your space heating and cooling, and water heating are the largest energy users in the home. Insulating the attic, crawl spaces, and basement rim joists, the areas usually ignored during construction, is the best way to upgrade the seal of your home to reduce the amount of outdoor to indoor air exchange. In this way, you’ll reduce the capacity of the systems needed, reducing cost when you replace it, and the ongoing utility costs of the fuels they need to operate.

25%

15%

Reduction in air infiltration

Savings on your heating & cooling costs

Resources

Imagine, for a moment, that this system and it’s connected ductwork are in your attic. As with many homes, your attic has insulation under the system in the floor. The insulation’s purpose is to reduce air infiltration to the finished rooms below.

Leakage in ductwork is common and difficult to avoid. Some of the ductwork may also be uninsulated in areas. The heating/cooling system itself has minimal insulation built in.

If the entire attic envelop isn’t insulated, the air temperature in the space is far closer to the outdoor temperature, in some cases worse. It’s not uncommon for an attic to reach over 100° in the summer. So now imagine that 100° air is leaking into the system and ductwork counteracting the unit’s attempts to cool that air. It has to work harder and be sized larger to meet the cooling requirement. The same happens in the opposite way in winter.

Now let’s take a look at a sealed attic. The attic now becomes part of the conditioned interior of the home, protecting the system from extreme temperatures and resolving the counteracting effects of air leakage into the ductwork.

This system will use less energy and won’t need to be sized as large to keep the house at a consistent temperature.